On April 14, the fourth kaizen case study meeting of the Daicel Group was held at Polyplastics’ Fuji Plant. Polyplastics designated April 7-10 as “Kaizen Week,” during which rehearsals for the presentations, a plant tour, and an exchange meeting were held.

What is the Kaizen case study meeting?

The Kaizen case study meeting is a venue for presenting cases of daily kaizen activities undertaken in departments and groups. Presenters do not report only results but also tell about the content and process of the improvement activities undertaken, explaining the problem they noticed, the ideas they came up with to resolve the problem, and the actions they took.

April 9 Plant Tour

A tour of the Fuji Plant was conducted in the afternoon on the day before the presentations were given. Before the tour began, Plant Manager Masamichi Mitsuuchi gave a talk in the seminar room introducing Polyplastics, the company’s history, the history of kaizen, and the corporate philosophy that is the Polyplastics-way. Then everyone toured the POM and compound plants and the danger experience school. It was a good opportunity for the participants to learn about the kaizen activities the company has undertaken thus far.

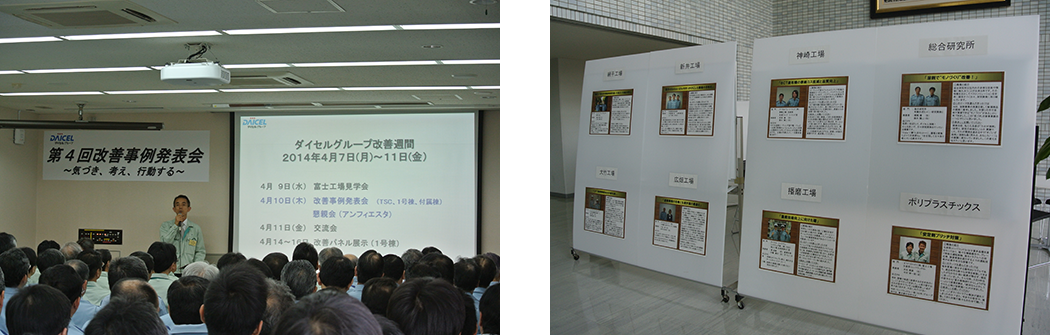

April 10 Presentation Meeting

Presentations were given by the 8 teams—6 plants and 1 laboratory from the Daicel Group and Polyplastics Fuji Plant—who won first prizes in the preliminary presentation meetings held at each site .

Representing Polyplastics were Mr.Masahiko Ikeda and Mr.Shinichiroh Nakamura from the Compound Group in the Production Division at the Fuji Plant who gave a presentation on “Countermeasures for Masterbatch Clogging.” Specifically, they described the problem of clogging in the masterbatch stock tank that occurred frequently in the summer due to consolidation and other causes. They related the uphill struggle they had pinning down the causes and coming up with kaizen measures to resolve the problem and the results of the measures that were implemented.

Managers and engineers from our PTW, PAP, PTM, and PNL group companies attended this year’s kaizen case study meeting for the first time. At the end of each presentation the presenters and audience engaged in a lively question-and-answer session during which they were able to share a variety of cases of kaizen.

After the presentation meeting, everyone moved to a banquet hall called Anfiesta in Fuji City for a social gathering. Each team was presented with a certificate of commendation and they were praised again for their hard work. Daicel Corporation’s Arai Plant was chosen to be the venue for next year’s kaizen case study meeting and Plant Manager Mitsuuchi passed the baton to Plant Manager Naito.