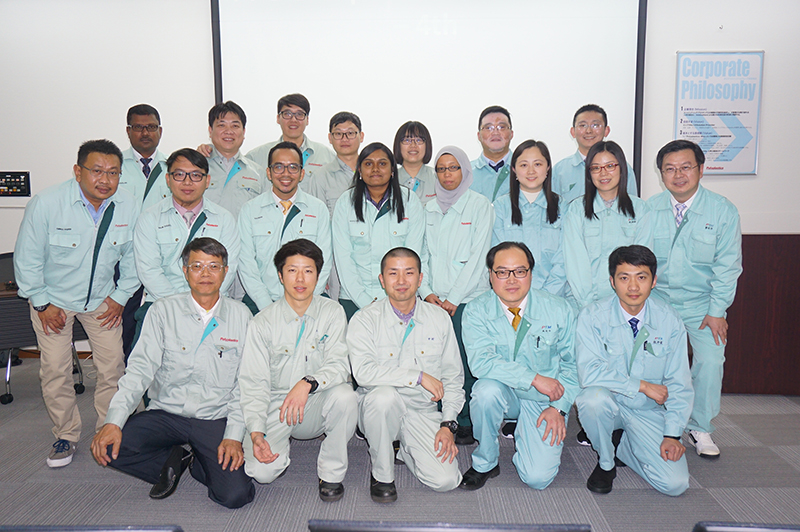

At Polyplastics, PPC Group Kaizen Convention has been held every March since fiscal 2015, as an opportunity to enhance “Kaizen sprit” within the whole group. This year, 9 representative teams from 5 production bases gathered at Fuji area and presented their own trial & error Kaizen processes.

As each presentation was full of passion and awareness, it took time for the judges to decide the awards. After careful discussion, the following teams were chosen to be the winner. Here we introduce the brief summaries of their presentations.

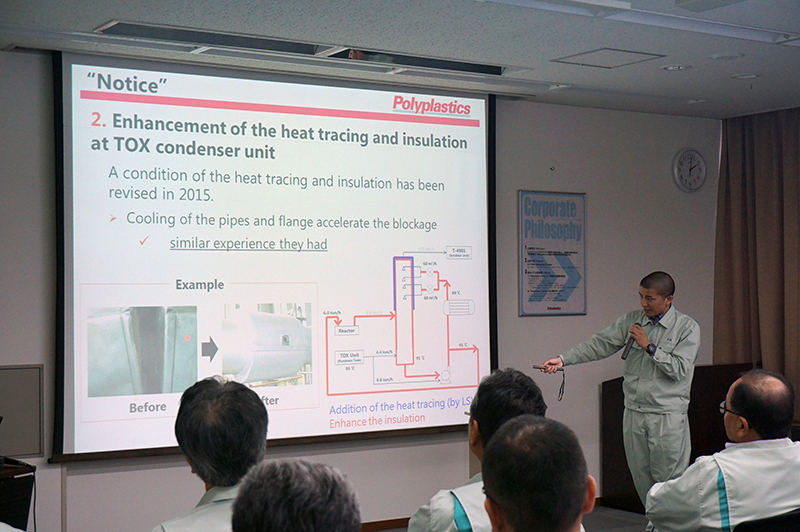

Best Presentation Award

Theme: Prevention for LCP Irregular Pellets

Theme: Prevention for LCP Irregular Pellets

Site: PTW PD2(Compound)

Presenter: Mr. Kuancung Ting, Mr. Weiyu Huang

In response to complaints from customers, they classified irregularities that were occurring in the shape of LCP pellets into 4 categories, and implemented Kaizen starting with the category with the highest rate of occurrence. Their presentation that showed us 1. Current situation analysis⇒2. Clarification of causes ⇒ 3. Appropriate responses that were steadily and carefully implemented was indeed a model example of Kaizen activity.

Presentation Award

Theme: Improvement of job efficiency through customized i-Ren and Excel training

Theme: Improvement of job efficiency through customized i-Ren and Excel training

Site: PAP MIS/HR

Presenter: Ms. Malani Manimaharan, Ms. Hasmah Binti Hussin

To reduce trouble with use of i-Ren and improve work efficiency, they made their own instructional materials to learn the know-how of Excel necessary for i-Ren and related work, and carried out training for the persons in charge to help increase efficiency. It was impressive that they didn't rely on outside training but made their own training program in the context of the actual situation on the ground.

Presentation Award

Theme: Zero Mis-Delivery 2.0 version

Theme: Zero Mis-Delivery 2.0 version

Site: PTW ADM/MM

Presenter: Ms.Chientzu Liu, Mr. Zhaoru Lin

The presentation dealt with efforts to reduce packaging trouble (ripped product bags, etc.) that was an extension of the zero Mis-delivery activity they had been working on previously. They got plant operators and personnel in other departments involved in the effort to devise check sheets, directions, and standardization that would enable everyone to produce the same quality of work. It was impressive to see an approach that aims to carry on and further improve Kaizen activity of superiors.

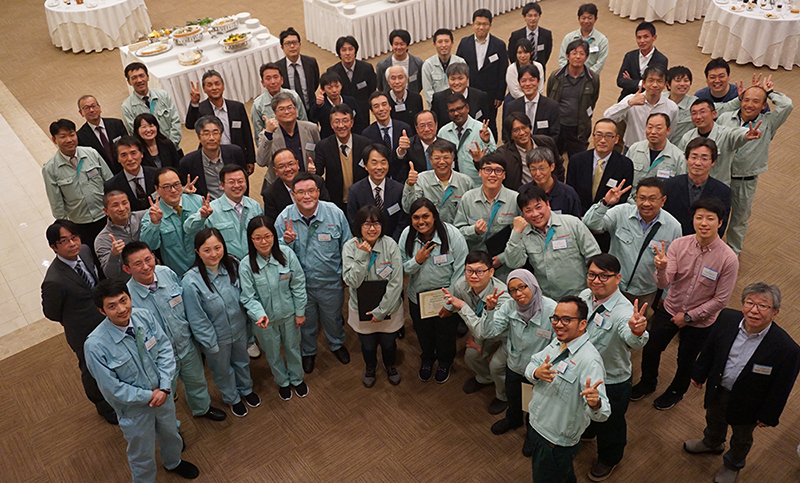

Thanks for all the presenters, the Kaizen Convention resulted in a great success. On the last day, they went on a short excursion. They enjoyed good old town and latest popular spot of Tokyo as well as the snow that is rare for this time of year.

Written by Ms. Maiko Omura