The 4th Polyplastics Group Kaizen Convention was held in the TSC seminar room on Thursday, February 4.

The following eight teams selected from among 122 teams gave presentations on their kaizen activities.

| Theme | Section |

|---|---|

| Countermeasure for temperature of bearing on aeration tank blower motor of wastewater disposal equipment | Production Department, Energy Group |

| Kaizen of TSC tensile property data for unfilled grade DURACON® | Technical Solution Center |

| Countermeasure for color irregularity of 1130A1T and 1140A1T gray pellets | Production Department, Compound Group |

| Countermeasure for printing defects on PBT product packages | Polypla Service Co., Ltd. |

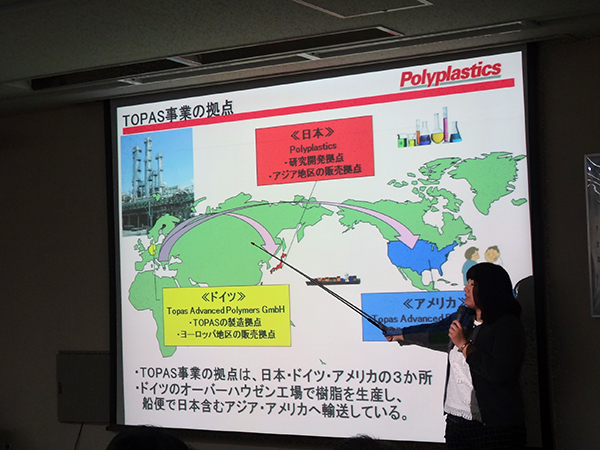

| Streamlining of orders for TOPAS placed to TAP GmbH | New Business Development, TOPAS Business |

| Kaizen of pellet color difference measurement environment | Production Department, Polymer Group (POM) |

| Countermeasure for film grade Vectra A950RX product for Kuraray | Process Development Center |

| Kaizen of equipment and utility suspension operations during PBT/LCP Plant short SD period | Production Department, Polymer Group Production (PBT/LCP) |

This year is the fourth year of kaizen activities undertaken by the Polyplastics Group. Managing Executive Officer Yasutoshi Segizawa gave the opening greeting with strong words of encouragement: "I am heartened to see so many of you engaged in kaizen activities as a natural part of your daily work. However, I also see some department teams having trouble deciding on a kaizen theme or finding the time for kaizen activity. I will continue to make every effort so that the circle of kaizen activity extends throughout the entire company in all of our group companies."

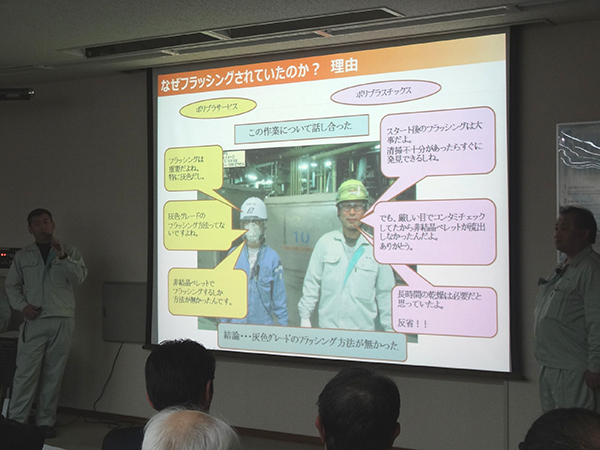

All of the teams gave easily understandable presentations on themes such as problems encountered in the course of daily work or potential problems with a high risk of surfacing. The presentations included accounts of the ideas exchanged by team members at the worksite and discussions with teams from other worksites in order to arrive at solutions.

The convention was attended by executive officers and kaizen promotion committee members in the Fuji area, and also kaizen promotion committee members from Tokyo, Osaka, and Nagoya, who participated in lively question and answer sessions at the conclusion of presentations.

The judges awarded the first prize to the Production Department, Polymer Group Production (PBT/LCP) for its presentation "Kaizen of equipment and utility suspension operations during PBT/LCP Plant short shutdown period." The prize for excellence was awarded to the Production Department, Compound Group for its presentation on "Countermeasure for color irregularity of 1130A1T and 1140A1T gray pellets."

President Goto remarked. "It was evident from all of the presentations that you approached the problem by exploring ideas and searching for a solution as a team. Solving problems by making steady effort as a team and contributing to the company in this way, is the dynamic force of the Polyplastics Group--something that isn't found in the business styles of Europe and America. As a result of this approach, each team got many people involved and went through a process of trial and error in taking another look at the worksite and reconsidering the matter for improvement. And there was always a turning point that led to a solution. What I felt most strongly as I listened to your presentations was that results were achieved because each person on the team had a strong desire to make an improvement or find a solution to the problem. I would like to express my gratitude to you once again for your hard work and hope that you will continue to actively undertake kaizen activities as united teams.

The team that won the first prize will participate in the Daicel Group's Kaizen Case Study Meeting, which will be held at the Kanzaki Plant in April. The team that won the prize for excellence will participate in the meeting with a poster exhibit. The two teams selected to participate will continue working on their kaizen activities and polish up their presentation and poster materials to prepare for the meeting. We wish these Polyplastics representatives the best of luck.

Ms. Maiko Omura