The 3rd Polyplastics Group Kaizen Convention was held in the TSC seminar room on Thursday, February 12.

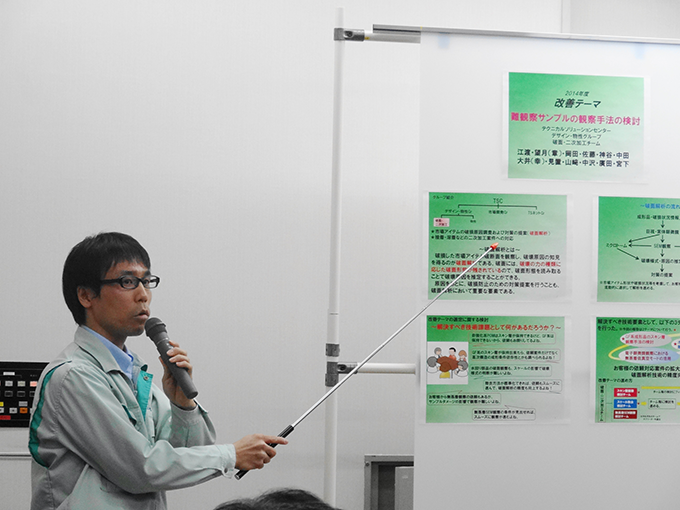

The following seven teams selected from among 123 teams gave presentations on their kaizen activities.

| Theme | Section |

|---|---|

| Improvement of the operating method of the hot air valve by using stress check sheet | Production Department, Polymer Group (POM) |

| Investigation of the observation techniques for the sample difficult to observe in the polarizing microscope or SEM | Technical Solution Center |

| Report of industrial waste reduction activity and promotion of the used paper bag recycling in Fuji plant | General Administration Department, General Administration Group |

| Countermeasures for the mechanical leak trouble in a water pump | Production Department, Machine Group |

| Improvement of the inventory management system for chemical agents’ shelf in QCD | Quality Management Department |

| Countermeasure for the printing failure in an auto bagging machine | PolyplaService Co., Ltd. |

| Solution of the water leakage problem in a compounding pelletizer and reviewing the self-maintenance activities | Production Department, Compound Group |

Each team gave a presentation on a problem encountered in the course of daily work or a potential problem with a high risk of emerging, described what they did to make the necessary corrections and improvements, and talked about how they exchanged ideas with co-workers at the worksite and discussed the problem with people from other worksites.

The convention was attended by executive officers and kaizen promotion committee members in the Fuji area, and also kaizen promotion committee members from Tokyo, Osaka, and Nagoya, who participated in lively question and answer sessions after the presentations were given.

The first prize was awarded to the team from the General Administration Department for its presentation “Reduction of industrial waste, charge for used product packages.” The prize for excellence was given to two teams: the Polymer Group (POM) for its presentation on “M-288D hot air valve operation improvement,” and PolyplaService for its presentation on “Countermeasure for defective Du-3 bottom surface printing.”

President Gotoh remarked, “I’m very pleased and thankful to see how seriously all of you approach problems that occur, discussing what to do and getting people from other worksites involved in order to improve and correct each problem. I hope you will continue to take every problem you notice seriously, no matter how minor it may seem or how large or small the effect of an improvement may be. This is the best way to get more people involved in kaizen activities.”

Representing Polyplastics, the team that won the first prize will participate in the Daicel Group’s Kaizen Case Study Meeting, which will be held in April. The two teams that won the prize for excellence will participate in the meeting with panel exhibits.

The three teams chosen to participate will continue working on their kaizen activities and polish up their presentation materials to get ready for meeting. We wish the teams the best of luck.