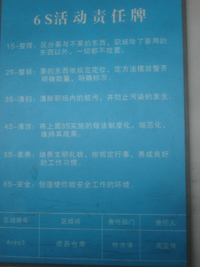

The so-called 6S Management means SEIRI, SEITON, SEISO, SETKETSU, SHITSUKE and SAFE. We put this management system into practice with the goal of letting our working staff is more aware of responsibility and importance of product quality and thus can decrease unnecessary waste of products and service.

In PTM, ESH section was responsible for the promotion of this project. A series of activities were arranged.

6S learning

During before years, some training courses about 6s were given to line-supervisor, and after the learning, they train first-line employee and lead them to use the leaned tool to keep their workshop in good condition. During before years, some training courses about 6s were given to line-supervisor, and after the learning, they train first-line employee and lead them to use the leaned tool to keep their workshop in good condition.

6S Patrol

They arrange 6S patrol every month. There are three inspection groups to carry out comprehensive and meticulous assessment on the 6s management. And the result shall be discussed, and analyze the root cause as well as the countermeasure. Through this way, 6s of workshop were improved continuously. Attached you can see some photo, that was some issue need to improve which be found during the patrol inspection.

Cleaning

The last work day of each month, all employees participated in cleaning work for 1 hour. This is the activity to let all employees have the consciousness that everybody has the responsibility to keep our 6s in good condition. And also the good 6s management can help us benefit from it.

High level of 6s promotion

The top management has paid much more attention to this job. Now we are planning to invest external trainer to make customized solution for us. We wish our 6s management can enter into a high level. Later, if have opportunity I will give detail report on it.

|