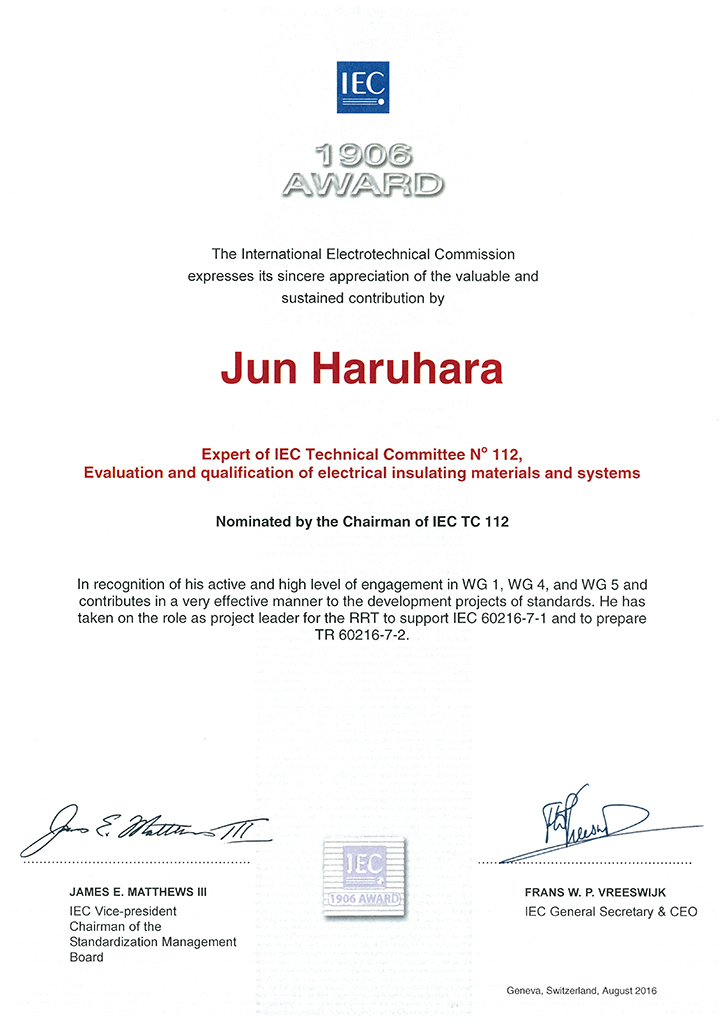

In October 2016, Mr. Jun Haruhara of the quality assurance department in PPC was given the IEC 1906 award. The award recognizes the exceptional achievements of world experts in the International Electrotechnical Commission (IEC), an organization that provides a platform to companies, industries, and governments for meeting, discussing, and developing the international standards they require. P-Mates had an opportunity to interview him.

P-Mates : Congratulations on the award, Mr. Haruhara. What is IEC and which of their standardizations are relevant to our company?

Mr. Haruhara : The Polyplastics family must have heard ‘ISO,’ the acronym for International Organization for Standardization. The ISO is one of the biggest international standardization bodies. You can find the standard numbers on our website and our brochures. The ‘IEC,’ meanwhile, is another big international standardization commission especially focused on electronic and electrical (E&E) products, systems, and their evaluations and qualifications. The IEC standards are familiar to us in terms of electrical properties test method for plastics. But remarkably, it is more important to us that our downstream customers comply with the IEC safety standards for their individual products (e.g., appliances, IT/AV equipment, and their components) to ensure that they comply with safety regulations set in many countries globally against risks such as electrical shock, fire, and environmental or human health impacts during and after use.

P-Mates : Why are their standards so important to us and how are you involved in IEC?

Mr. Haruhara : Along with the evolution of technology, safety issues of the products have been changed. The standards are revised sometimes with stringent protocols, at other times with relaxed criteria that affect material competitions. Anyone can provide comments to a draft for revision through the national committees. However, the decision to accept or reject a comment is made only by the IEC meeting participants as national delegations representing the end-product companies, suppliers (including the plastics industry), or certification bodies who are actually influential to the industry and the market. In previous years, European delegates led the decision-making process, but recently ‘global reach’ has become the trend in the IEC, because cutting-edge E&E technologies are instantly available around the world now and non-EU opinions have become more important. To represent Japan and cover the Asian market, Polyplastics and I have been involved in the IEC for a number of years. I have participated as a national delegate since 2008, drawing from my experience as a chairman of a material committee of the Japan Plastics Industry Federation (JPIF).

P-Mates : Please let us know your comments on the award and your plan for the next step.

Mr. Haruhara : I was awarded for leading a project team to accelerate a long-term thermal aging test for plastics from an IEC committee working on the evaluation of electrical insulation material. There were members from BASF, SABIC, Solvay, SIEMENS, TE connectivity, UL and some testing laboratories. Honestly, it was a very hard management task to facilitate and moderate competitive opinions, but it yielded an IEC official technical report that is expected to serve as a reference for UL in their work to reduce the time and cost for their evaluations and meet the market demand for faster certification. With the confidence I have garnered from the achievement, as well as my appreciation to the supporting company, I’m currently leading a new sub-team of the project focused on ‘low-halogen definition’ in another IEC committee concerned with unfavorable impacts on our industry. Based on the Polyplastics-Way, I would like to keep the best practices in order to create meaningful and valued standards for the supply-chain and our customers. I also hope more experts in the Polyplastics group will start to work in their individual fields of standardization for to apply their achievements to our whole business.

P-Mates : Thank you for your time.

P-Mates editorial team