At Polyplastics, in addition to the Fuji Plant, “kaizen” improvement activities are also being energetically advanced at the Research and Development Division, the Tokyo Head Office and individual branches. These endeavors, which continue to grow more spirited each year, are also expanding to Group production bases. As one example of this, on March 25 the Second PPC Group Kaizen Convention was held at the Fuji TSC Seminar.

Traveling to Japan for this event were seven teams from PAP, PTM, PTW and PNL, with the two teams from PPC raising the total number of presenting teams to nine (with 18 presenters taking part).

At the opening ceremony, President Noboru Goto appeared as the guest speaker, extending warm words of welcome and encouragement to the scheduled speakers. President Goto’s remarks included:

“The Company is truly supported by the kaizen activities that all of you continue to faithfully advance. In that regard, even if the results of the individual measures are limited, together they add up to great successes for the Group as a whole. Today, we hope to use this Convention as an excellent opportunity to accumulate problem-solving ideas and processes in order to share our common wisdom and push on ahead. “

During the Convention, presentations were used to address the following themes.

Theme |

Site/Section/Presenter name |

|---|---|

Comprehensive Training Module |

PAP/ NPP (POL/FIN MP2) |

Power saving activities in Water System |

PTM/ Monomer Department |

Countermeasure of metal contamination for LCP grade |

PPC/ Production Technology Office, Production Machinery Gr |

Prevent pellet plugging in channel of metal checker |

PTW/ Production Department-2 (Compound) |

FPP Grade change cleaning improvement |

PAP/Productuion FPP Department (Compound) |

Improvement of operation for pulling screw out |

PPC/ Compound Group |

Blower power saving for pneumatic conveying system |

PTW/ Engineering & Maintenance Department |

Continue to improve OR-U feeding system in PNL |

PTM/ Instrument |

Within the individual team presentations, mention was made of the difficulties of the issues faced on an everyday basis, trial-and-error struggles and other tough challenges. The impression was also generated, however, of the passion being devoted to dealing with such adversity. While the presenters appeared somewhat tense as they spoke, their expert use of PowerPoint in narrowing down the volume of information being conveyed, the bold approaches of introducing the information and other skills translated into truly fine performances. At the question-and-answer sessions, Chinese and Japanese were used in addition to English to help deepen the understanding of the full audience. That also generated brisk and fruitful exchanges of opinions and ideas.

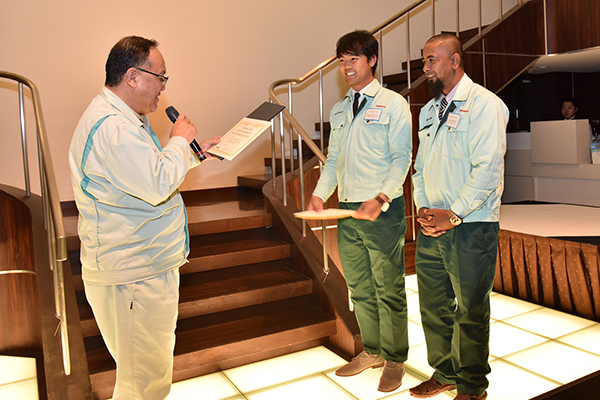

A friendly get-together was held after the Convention. Featured were powerful speeches by leaders from representatives of each Group Company, announcements of the Convention results and an awards ceremony. Honored with Best Presentation Award was the PAP NPP (POL/FIN MP2) team. Based on the question of “Are we competitive?” that effort involved enlisting the support of veteran staffers in the preparation of a manual from the perspective of new employees.

At this Second Kaizen Convention, experiences were mutually shared to help better learn the processes of becoming aware of issues, thinking and acting. The event also provided a highly meaningful occasion to actively develop the fruits gained from specific business sites at other Group locations. It is our heartfelt hope that such improvement programs will be continued from here on as well, thereby emerge as a driving force behind the growth of the Polyplastics Group as a whole.

Ms. Maiko Omura